Panasonic Welding Robot Repair & Maintenance

Panasonic Welding Robots and Their Maintenance Needs

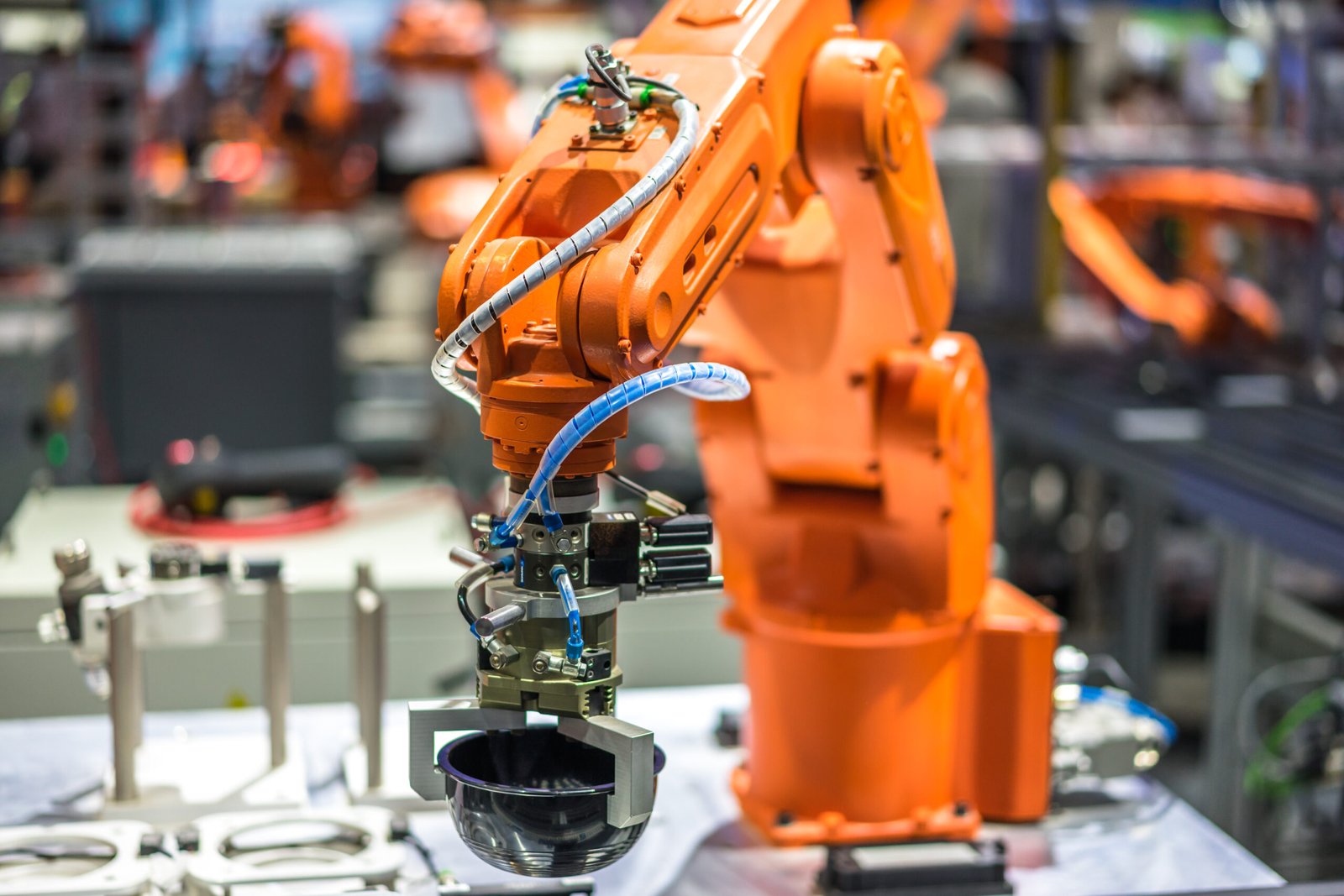

Panasonic’s welding robots are the workhorses of many industrial manufacturing lines—particularly in automotive and heavy fabrication environments. These robots are trusted for their speed, repeatability, and clean weld performance. But like any piece of automation, they require regular service to keep working at peak efficiency.

Our team delivers expert Panasonic robot repair and ongoing support for TM, TAWERS, and other Panasonic robotic welding systems. Whether your system runs integrated arc-welding tasks or high-speed spot-welding processes, we perform the mechanical and software-level service needed to reduce downtime and restore cycle accuracy. Preventive care isn’t optional with Panasonic robots—it’s essential to long-term production stability.

Troubleshooting Panasonic Robot Power Supplies and Drives

Panasonic’s servo systems and welding power supplies are tightly integrated with robot motion. When something fails, diagnosing the exact cause takes deep system knowledge. Our technicians have years of hands-on experience with Panasonic robotics service, specifically with servo motors, drive amplifiers, torch cables, and control unit faults.

From arc instability to servo overcurrent errors, we perform comprehensive fault tracing. We handle power source disconnections, feedback loop breakdowns, and signal interference between welding head and robot control. If your robot stops mid-weld or begins running inconsistent seams, our team can isolate the issue and provide quick, lasting repair.

Enhancing Performance of Panasonic Robotic Welders

A welding robot isn’t just about moving an arm—it’s about creating clean, strong, consistent welds across thousands of cycles. If your Panasonic robot isn’t hitting its marks, we don’t just “fix it”—we optimize it.

Our Panasonic welding robot maintenance includes full weld parameter review, torch path tuning, wire feed calibration, and nozzle wear inspection. We also review cycle timing and analyze any deviation in bead consistency or penetration. Whether you’re using a fully integrated TAWERS system or standalone welding controls, we help you achieve higher throughput and better-quality welds with every shift.

Support for Robotic Welder Retrofits and Reprogramming

As your production needs evolve, your robotic welders must adapt. We provide retrofitting services for Panasonic robots, helping facilities upgrade hardware, expand capabilities, or meet new part requirements without replacing the entire unit.

Our services include reprogramming weld paths, re-teaching joint motions, integrating new jigs or safety devices, and updating control software. If you’ve moved a Panasonic robot to a new cell or introduced different parts, we make sure the robot adapts to its new role without missed cycles or weld quality drop.

Common Robotic Welder Faults and How We Solve Them

Some of the most common problems we encounter in robotic welder repair involve intermittent faults. These are harder to track—and harder to fix—without experience.

If your Panasonic welding robot is experiencing erratic arc starts, off-path wire placement, or servo drift, we start with full system logs and work backward to identify the trigger. Our team knows the quirks of Panasonic’s torch movement and weld current synchronization. From loose encoder cables to cracked feedback boards, we’ve seen it all—and fixed it all.

Our Panasonic Robotics Support Process

Our robotic welder repair services are comprehensive and designed to restore your Panasonic robots to peak performance. Whether your robot requires routine maintenance or an emergency repair, we are here to help. Our process includes diagnostics, repair, calibration, and post-service support to ensure that your robots remain reliable.

Diagnostic Services:

We begin with an in-depth diagnostic check to identify any issues with your Panasonic welding robots. This ensures that we are addressing the root cause of the problem, rather than just the symptoms.

Expert Repair and Calibration:

Our technicians are equipped with advanced tools and knowledge to handle any repair or calibration task. Whether it’s replacing a faulty part or recalibrating the robot’s systems, we ensure that your Panasonic robots operate efficiently and accurately.

Get Your Panasonic Robot Back in Action Today!

Is your Panasonic robot experiencing issues? Don’t wait until it’s too late.

Contact our team today for expert repairs, preventative maintenance, and software updates.

We’re here to get your Panasonic robotic systems back up and running at peak performance, with minimal downtime.

Talk A Robotics Integrator

By submitting this form, you agree to receive communications via phone, text message, and email. Message and data rates may apply. Your information may be shared with trusted third-party service providers solely for the purpose of helping you explore Section Robotic Intergration options. You also agree to our Privacy Policy and Terms of Service.

+1 463-257-9600

Success Stories: See What Business Have To Say About Robotics Integration

4.7 Customer Reviews