Industrial Robotic Palletizing Systems Integration

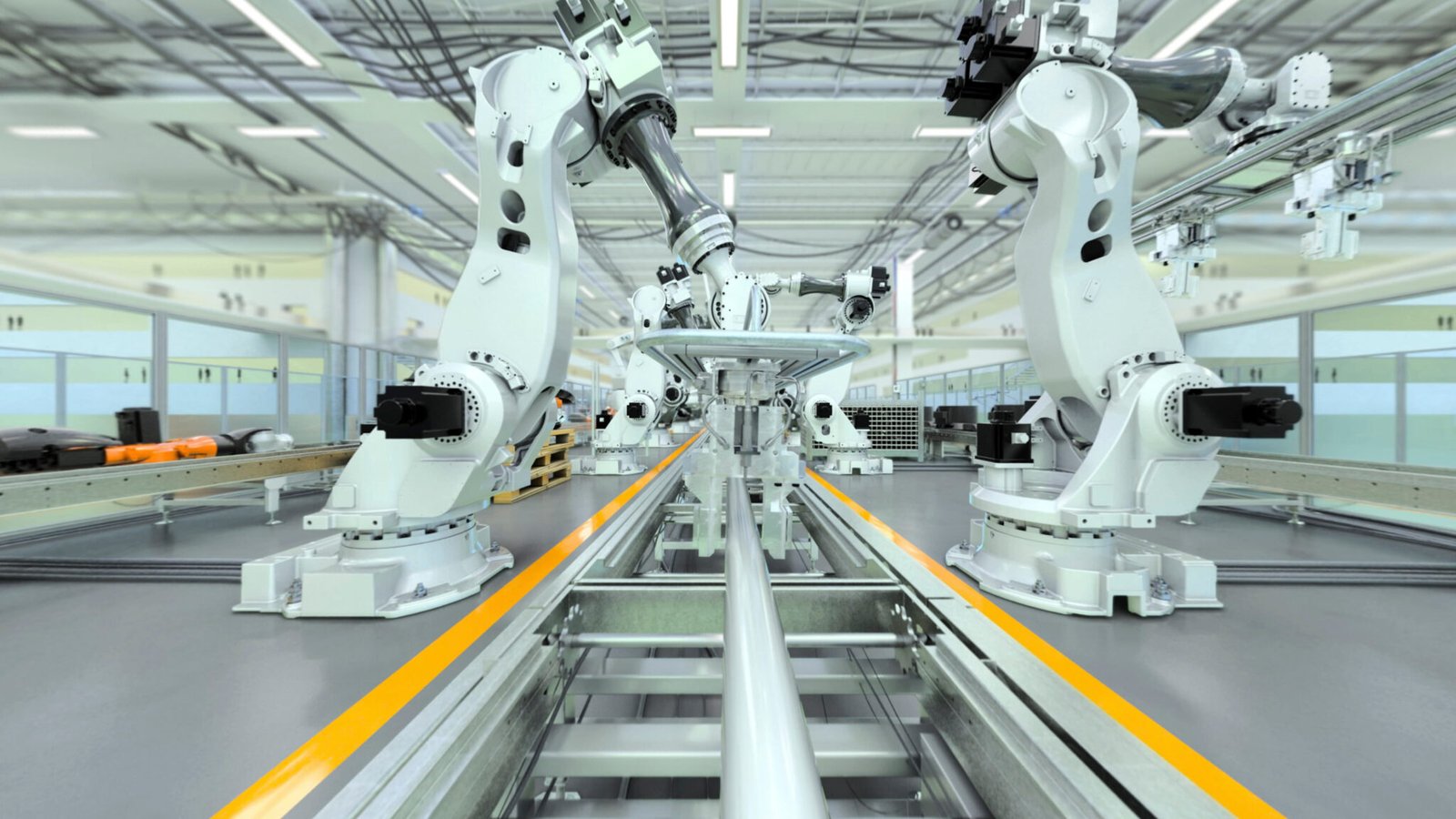

Overview of Robotic Palletizing Systems

Robotic palletizing systems are transforming the way manufacturers and logistics providers move products. By replacing manual stacking with automated palletizing solutions, companies can significantly reduce labor costs while increasing consistency, safety, and throughput.

Whether you’re working with cartons, bags, trays, or shrink-wrapped products, palletizing robots offer a flexible, high-speed solution for end-of-line packaging. These systems are a key component of modern industrial automation, delivering precision placement and consistent performance around the clock.

At Robotics Integration, we engineer complete robotic palletizing systems that are tailored to your facility, product mix, and growth goals—so you can streamline operations and scale with confidence.

Benefits of Automated Palletizing in Manufacturing

Automated palletizing offers more than just speed. It improves worker safety, optimizes floor space, and ensures that every pallet meets quality and load balance standards. For manufacturing plants under pressure to reduce costs and increase uptime, robotic palletizing is a strategic investment.

Traditional manual palletizing leads to fatigue, injuries, and inconsistent stacks. Robotic systems eliminate these issues with programmable precision. They maintain exact stack patterns, reduce packaging waste, and integrate directly into your existing conveyors and ERP systems.

Plus, with built-in diagnostics and predictive maintenance alerts, you stay ahead of downtime. Whether you’re running one production line or managing a large-scale distribution center, automated palletizing supports lean, efficient operations.

Types of Palletizing Robots & End-of-Arm Tools

Different applications require different robotic capabilities. That’s why we offer a range of palletizing robots and custom end-of-arm tooling to fit your products and workflow. From lightweight case handling to heavy-duty bag stacking, we build systems that meet your specific load requirements.

High-speed robotic arms are ideal for consumer goods and fast-moving packaging. Articulated robots provide flexibility for mixed-SKU environments, while gantry-style palletizers offer precise vertical stacking for heavier loads. We customize end-of-arm tooling to handle delicate items, multi-pack layers, or uneven surfaces.

Integrated sensors and vacuum or mechanical grippers ensure gentle, accurate placement across every shift. With robotics engineering at the core, each solution is built for real-world durability and performance.

Our Robotic Palletizing Integration Solutions

We deliver complete robotic palletizing systems—from concept to commissioning. Every system we design reflects a deep understanding of automation and engineering, tailored to your product flow, facility space, and throughput goals.

Our integration services include system simulation, mechanical design, robotic arm selection, control panel integration, and safety compliance. We incorporate conveyors, slip sheet dispensers, pallet dispensers, and wrapping equipment to create seamless end-of-line automation. Our team works closely with your operations and IT teams to ensure the system integrates with MES or WMS platforms, creating traceable, connected workflows.

Whether you’re automating a single line or redesigning an entire logistics center, we build systems that grow with you.

When to Invest in Robotic Palletizing

If your team is manually stacking products—or if current automation can’t keep up—then it’s time to consider robotic palletizing. Ideal use cases include high-volume production, short cycle times, and frequent product changeovers.

Companies in food & beverage, pharmaceuticals, packaging, and manufacturing often see rapid ROI from palletizing automation. Systems can be configured to run multiple SKUs, adjust patterns on the fly, and stack multiple pallet loads simultaneously.

By minimizing labor dependency and maximizing throughput, robotic systems unlock cost savings and process consistency in high-demand environments. And when you factor in long-term flexibility and uptime, the case becomes even stronger.

Key Features of Our Automated Palletizing Systems

Robotic palletizing isn’t just about speed—it’s about smart integration. Our systems include key features that improve every part of the palletizing process.

Each solution includes programmable stack configurations, product detection with vision sensors, automated pallet dispensers, and optional stretch-wrapping integration. Our systems use industrial automation controls to enable real-time adjustments, remote monitoring, and energy-efficient operation. We also build in redundancy and future scalability, allowing you to upgrade with minimal interruption. As automation companies increasingly seek modular, plug-and-play systems, our palletizing solutions are built to meet those demands head-on.

Let’s Build Your Palletizing Automation System

You don’t need to reinvent your workflow to take advantage of robotic palletizing. You just need a partner who understands how to engineer and integrate it right.

At Robotics Integration, we bring years of robotics engineering experience, a network of trusted automation vendors, and a proven integration process.

Let’s design and deploy a solution that increases throughput, lowers costs, and helps your team work smarter—not harder.

Talk A Robotics Integrator

By submitting this form, you agree to receive communications via phone, text message, and email. Message and data rates may apply. Your information may be shared with trusted third-party service providers solely for the purpose of helping you explore Section Robotic Intergration options. You also agree to our Privacy Policy and Terms of Service.

+1 463-257-9600

BOOK YOUR ROBOTICS INTEGRATION CONSULTATION

Connect with a Leading Industrial Robotics Integration Company Today

+1 463-257-9600

+1 463-257-9600

hello@roboticsintegration.com

If You're Not Using Robotics Integration, You're Leaving Money on the Table—Let's Change That!

Stop losing profits due to inefficient manual processes—Robotics Integration streamlines production, cuts costs, and boosts profitability immediately. Your Choice: Keep overspending on outdated methods... or start automating and save. Connect today for your personalized automation roadmap. Complete the form below, and one of our Robotics Integration Specialists will reach out promptly.

By submitting this form, you consent to receive SMS text messages, phone calls, and emails from Robotics Integration regarding your inquiry and related services. Message and data rates may apply. Reply STOP to opt-out of SMS communications at any time.. You also agree to our Privacy Policy and Terms of Service.

Success Stories: See What Business Have To Say About Robotics Integration

4.7 Customer Reviews