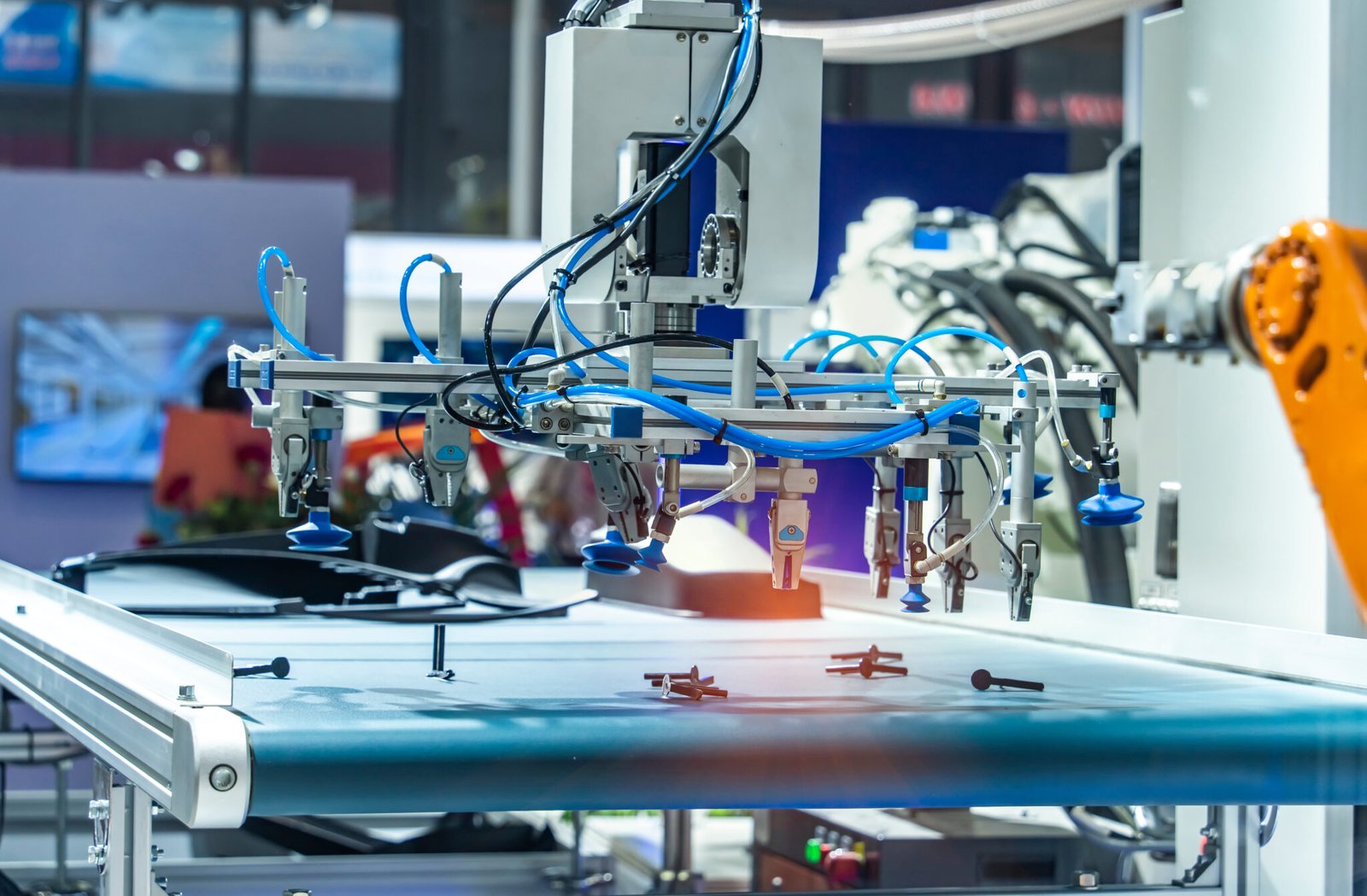

Our strength is custom robotics systems integration, and vision is one of the most critical parts. We don’t just install off-the-shelf gear. We design complete systems from optics to algorithms—aligned with your throughput, tolerance, and traceability needs.

Our expertise includes:

Multi-camera and 3D imaging integration

Optical component selection and mounting (lens, filter, lighting)

Image processing software (AI, deep learning, and rule-based)

Robot-vision calibration and hand-eye coordination

Part tracking across cells using barcode and vision-based ID

Data collection, MES/ERP integration, and quality analytics dashboards

Vision-guided robotic cell design and full industrial automation tie-in

We’ve deployed systems in environments ranging from cleanroom assembly to heavy industrial metal processing. If your production line needs precise inspection under pressure, we know how to make it work.